1-Pc OK | No MOQ. CNC Machining for Prototypes and Fast Small Batches. Instant quote

Content Guide:Discover how CNC machining enables custom manufacturing for industries like aerospace, medical, and automotive. Learn about precision machining, rapid prototyping, and how to choose the right CNC service provider.

In today’s fast-evolving industrial landscape, custom manufacturing is no longer a luxury—it’s a necessity. From aerospace components to medical implants, businesses increasingly rely on CNC machining services to produce high-precision, bespoke parts.

As a leading CNC machining factory, we leverage advanced 5-axis CNC milling, CNC turning, and Swiss machining to meet diverse industry demands. This article explores how custom CNC machining shapes the future of manufacturing and why it’s the best solution for personalized production.

CNC (Computer Numerical Control) machining offers unmatched precision, repeatability, and flexibility, making it ideal for low-to-high volume custom parts.

✅ Key Benefits:

Tight tolerances (±0.005mm or better)

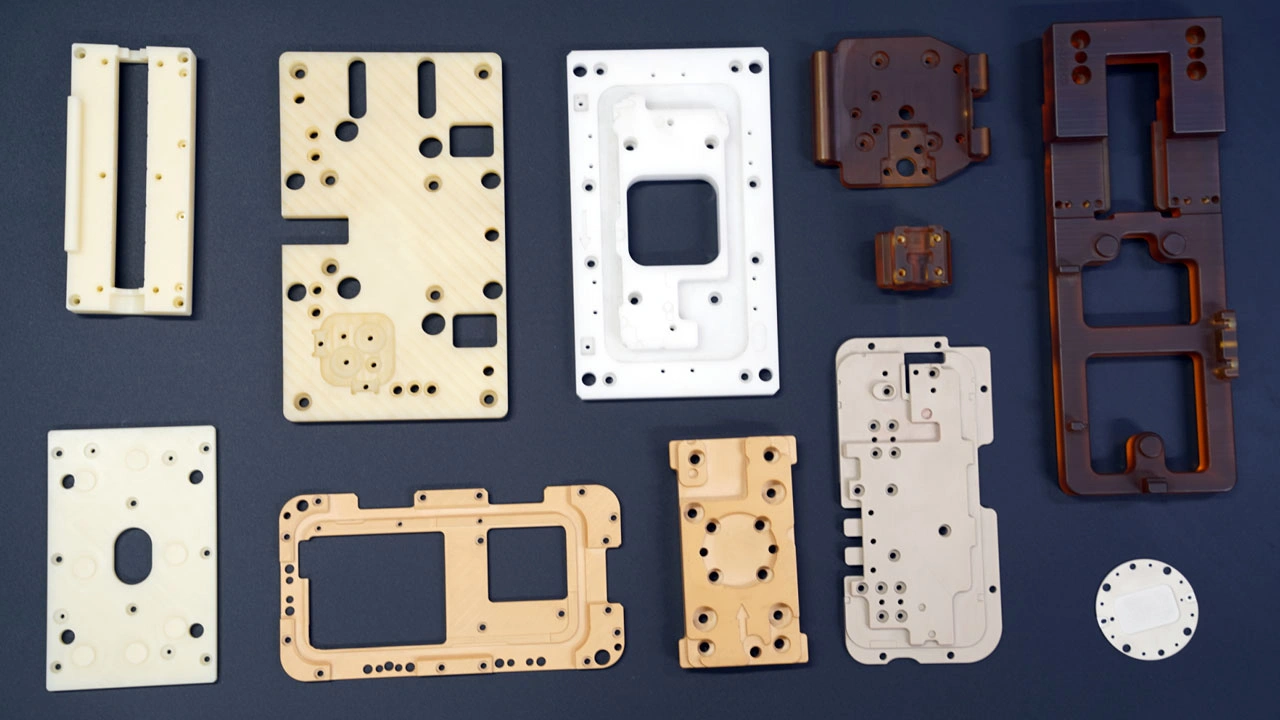

Wide material compatibility (aluminum, stainless steel, titanium, plastics)

Complex geometries (3D contours, micro-machining, thin-walled parts)

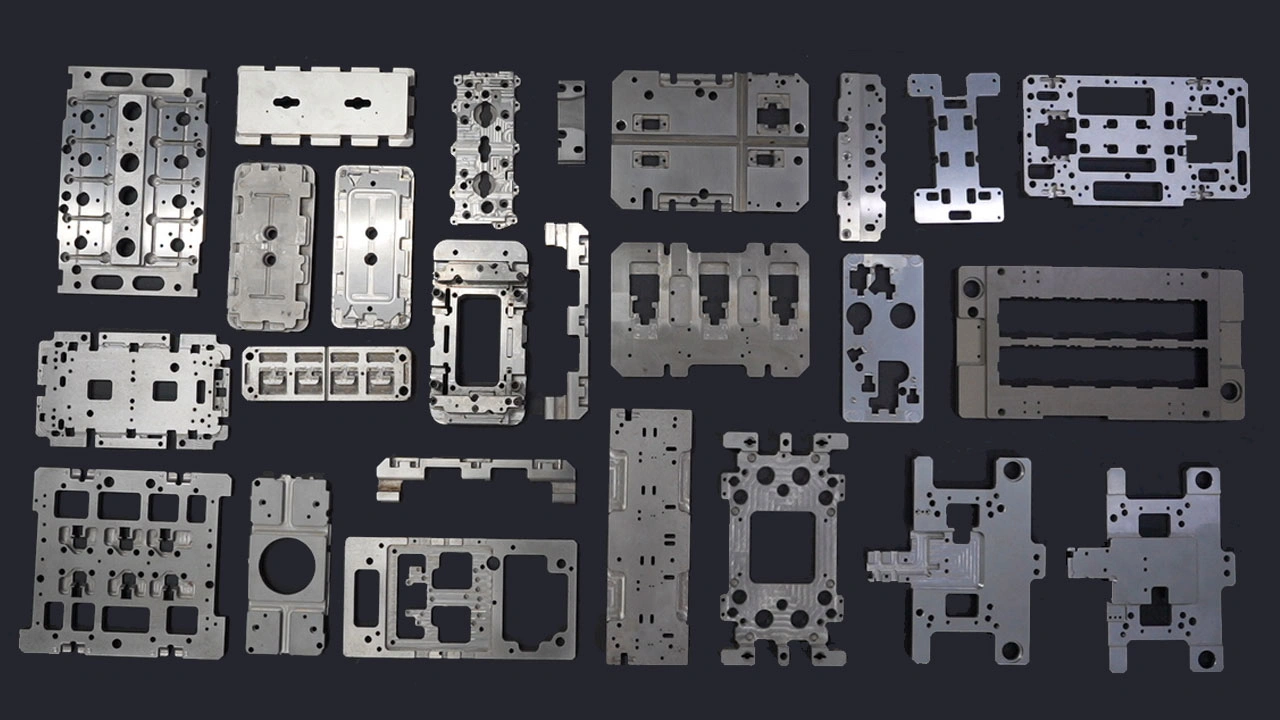

High-precision CNC machining aerospace components

The process ensures fast turnaround without sacrificing quality:

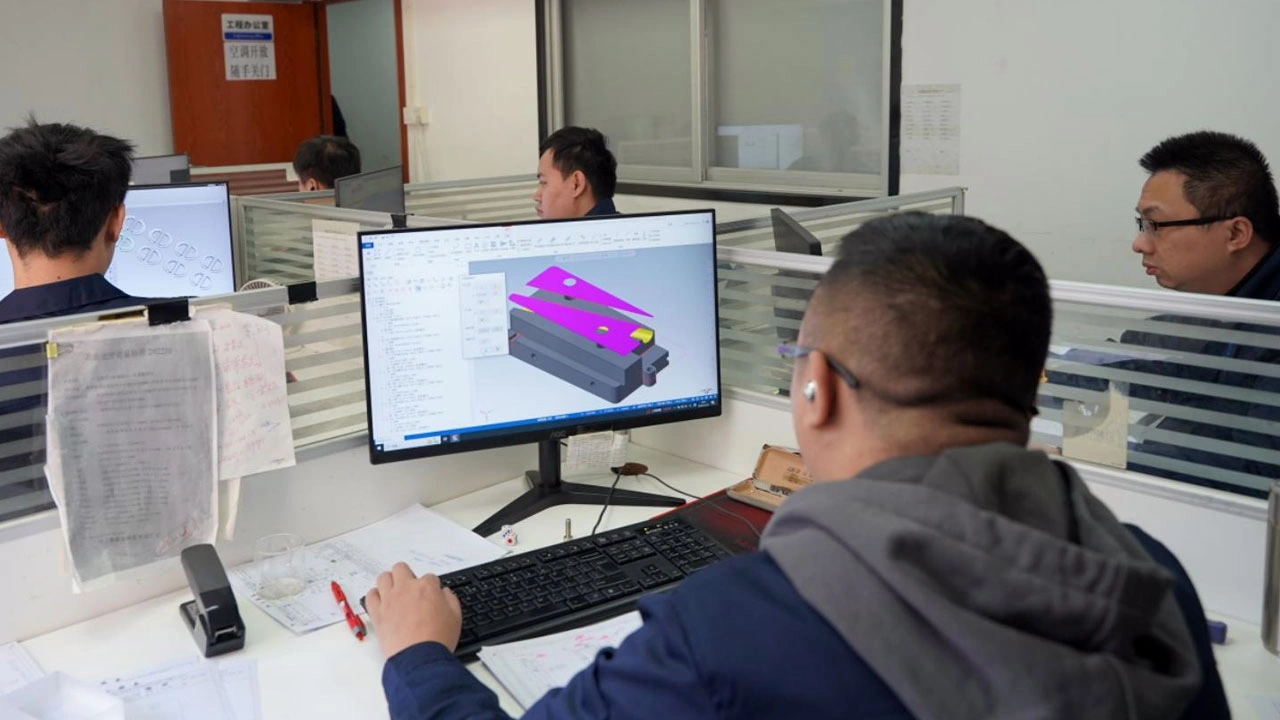

Design & Engineering – CAD/CAM modeling for optimal machining paths.

Material Selection – Choosing the right metal or plastic for durability and function.

Precision Machining – Multi-axis CNC milling/lathing for complex shapes.

Quality Control – CMM inspection, surface finishing (anodizing, polishing).

Engineer programming a CNC machine for custom parts

Medical – Surgical tools, orthopedic implants (ISO 13485 certified).

Aerospace – Lightweight, high-strength components (AS9100 compliance).

Automotive – Engine parts, transmission components, EV battery housings.

Consumer Electronics – Heat sinks, enclosures, connectors.

CNC-machined parts for medical and automotive applications

When selecting a CNC machining service provider, consider:

✔ Fast prototyping (3-5 day lead time)

✔ Material expertise (metals, engineering plastics)

✔ Certifications (ISO 9001, ITAR, AS9100)

Need custom CNC parts? Request a free quote today!

CNC machining is revolutionizing custom manufacturing, enabling faster, more precise, and cost-effective production. Whether you need prototypes or mass production, advanced CNC technology ensures your parts meet exact specifications.

(CTA: Get Your Custom CNC Machined Parts in 5 Days – Contact Us Now!)