1-Pc OK | No MOQ. CNC Machining for Prototypes and Fast Small Batches. Instant quote

Content Guide:Explore how 3D printing technology is transforming manufacturing with precision, customization, and innovation. Learn about applications in aerospace, automotive, and medical industries, and discover how Sunnyhowe Co., Ltd integrates additive and subtractive manufacturing for optimal results.

In the era of Industry 4.0, 3D printing technology is revolutionizing manufacturing at an unprecedented pace. As a core technology of the "Fourth Industrial Revolution," it is breaking through the limitations of traditional manufacturing and ushering in a new epoch of personalized customization.

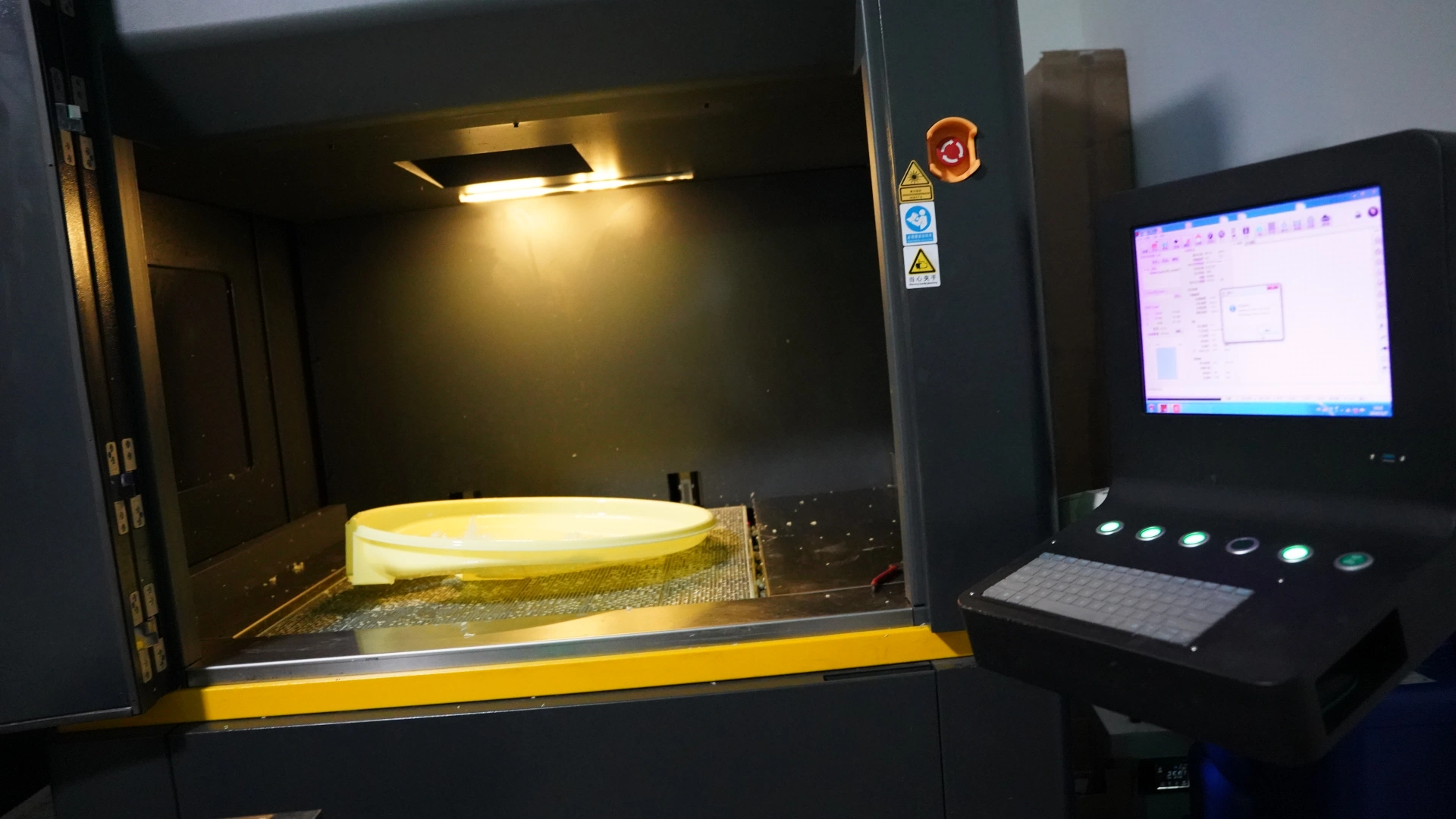

Metal 3D Printer Producing Precision Components - High-Accuracy Additive Manufacturing

3D printing, also known as additive manufacturing, constructs objects layer by layer, overcoming the constraints of traditional subtractive methods. In the aerospace sector, Boeing adopted 3D printing to produce fuel nozzles, consolidating 20 separate components into a single part. This innovation not only reduced weight by 25% but also extended the product's lifespan fivefold.

Complex geometries that were once impossible with conventional techniques are now achievable with 3D printing. GE Aviation's 3D-printed fuel nozzles feature intricate internal cooling channels that far surpass the capabilities of traditional manufacturing, improving engine efficiency by 15%.

Complex 3D Printed Component with Internal Structures - Advanced Manufacturing Technology

3D printing offers unique advantages in lightweight design. BMW Group utilized 3D printing to produce the i8 Roadster convertible roof bracket, which is 44% lighter yet 10% stronger—embodying the principle of "lighter and stronger" design.

As 3D printing technology matures, the manufacturing industry is shifting from mass standardization to personalized production. Adidas's Futurecraft 4D running shoes use 3D-printed midsoles to provide customized footwear tailored to individual consumers, offering a unique athletic experience.

Customized 3D Printed Products - Personalized Manufacturing Solutions

For industries reliant on high-precision components and on-demand production, 3D printing offers transformative potential. Applications range from aerospace parts and automotive components to medical implants and custom prototypes. Companies specializing in CNC machining services, rapid prototyping, and low-volume manufacturing can leverage 3D printing to enhance flexibility, reduce time-to-market, and offer more innovative solutions to their clients.

3D printing is redefining the DNA of manufacturing. It is not merely an alternative production method but a game-changing industrial revolution. With continuous advancements in material science and printing technology, 3D printing will unlock new possibilities and pave the way for smarter, more adaptive manufacturing.