1-Pc OK | No MOQ. CNC Machining for Prototypes and Fast Small Batches. Instant quote

Content Guide:Choosing a CNC manufacturer? Price is just the start. Learn the 5 key factors for quality parts, on-time delivery, and a partnership that ensures your project's success.

If you've ever sourced custom parts, you know the drill: send out your CAD files, wait for quotes to roll in, and then… choose the cheapest one. It seems logical. But that low number often comes with hidden costs: delayed timelines, unexpected quality issues, and endless back-and-forth that drains your time and energy. The right CNC machining manufacturer acts as a partner, not just a vendor. Here’s what really separates the best from the rest.

Engineers move the parts that need to be inspected

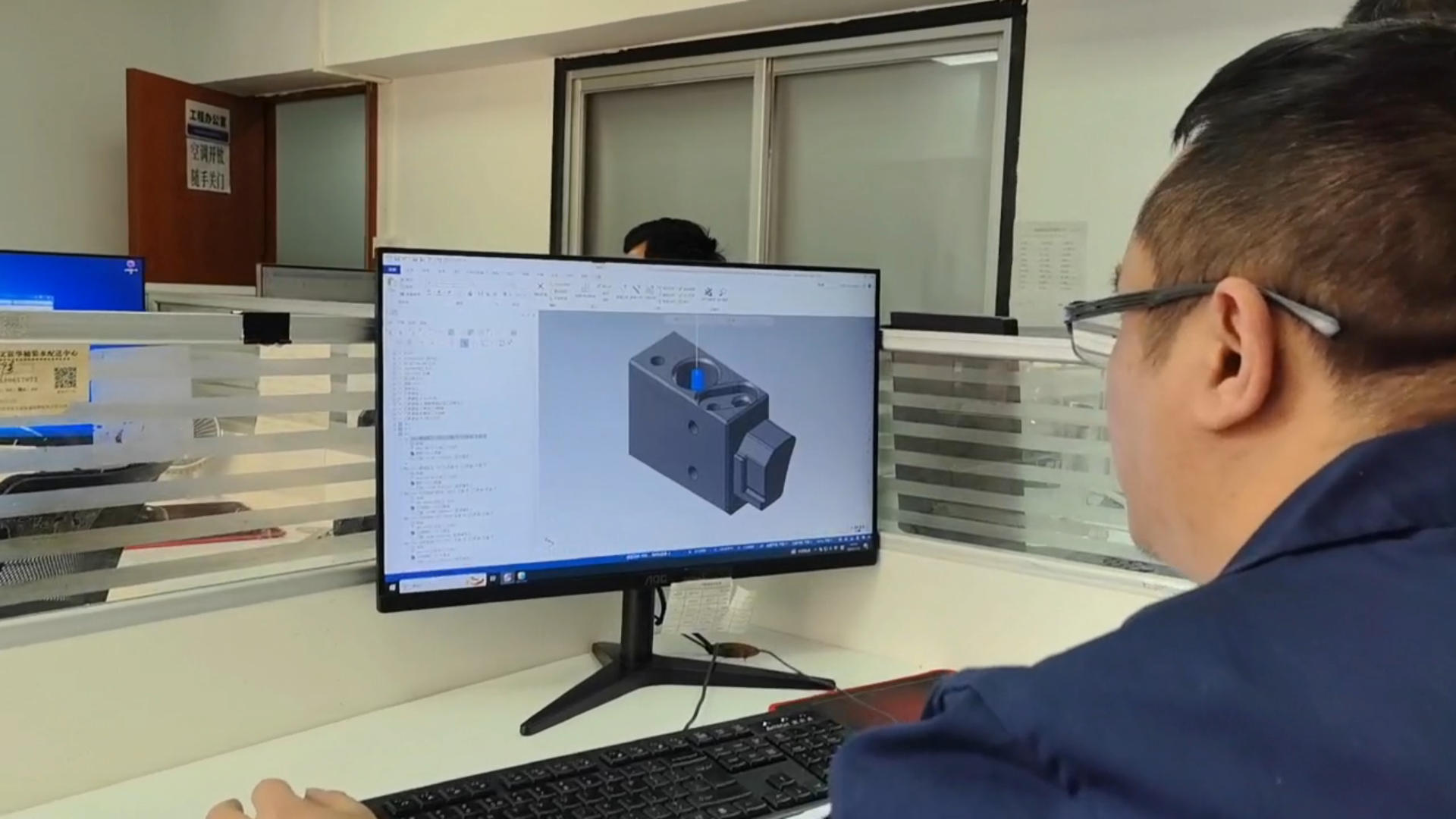

A parts supplier tells you the price. A manufacturing partner tells you how to make it better. The first sign of a true expert is their willingness to perform a Design for Manufacturability (DFM) analysis. This means they proactively review your designs to suggest modifications that reduce cost, improve strength, or simplify machining without compromising your part's function.

Ask yourself: Do they offer constructive feedback on my design, or do they just quote exactly what I sent?

CAD software showing DFM design optimization suggestions

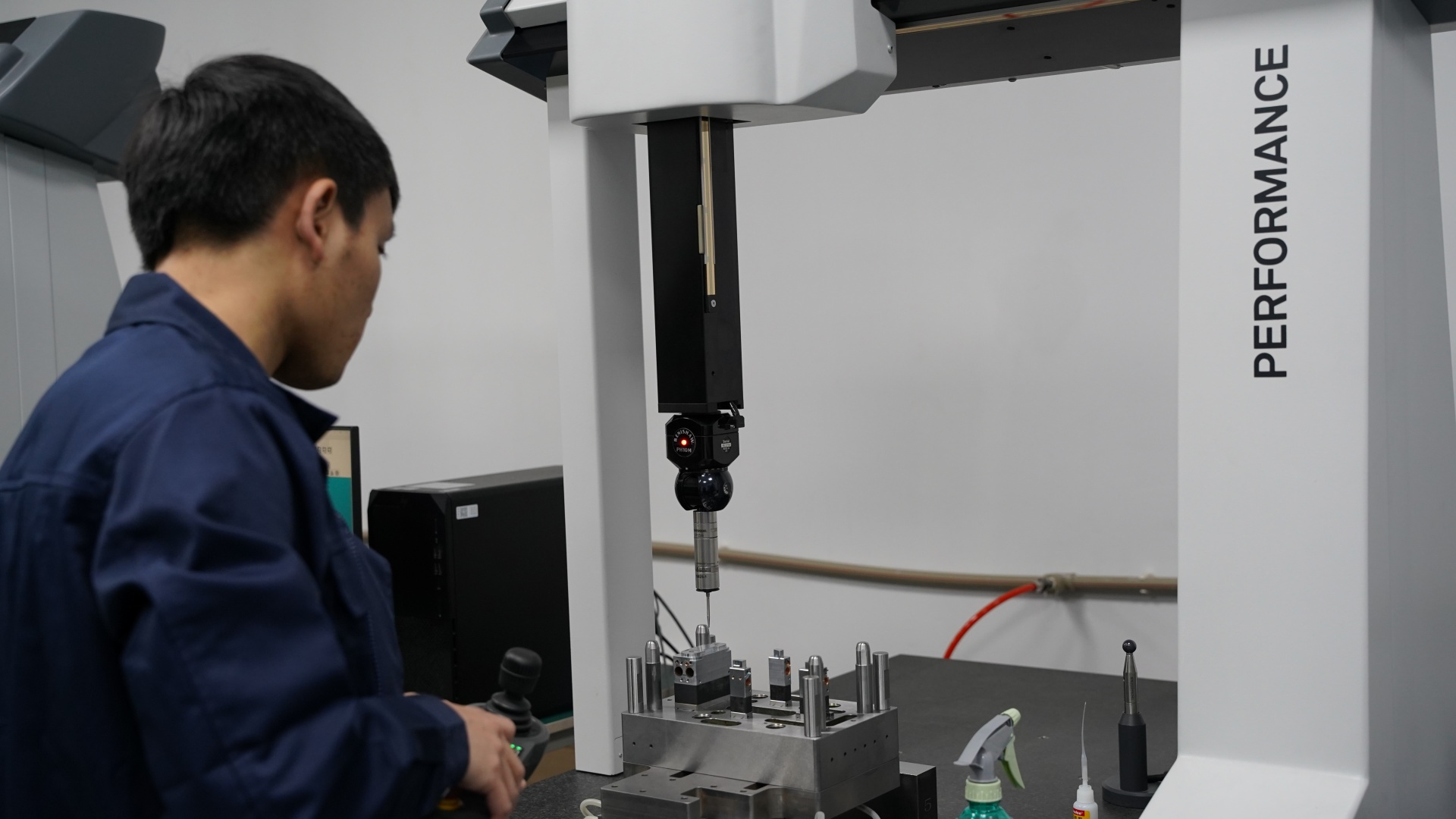

Anyone can say they care about quality. The proof is in their process. Look for a manufacturer with a documented quality system, like ISO 9001 certification. This isn't just a plaque on the wall; it's a promise of consistency. Ask about their inspection equipment—do they use CMMs, optical comparators, and other precision tools? Most importantly, will they provide inspection reports with your first articles?

Ask yourself: How do they prove that every part that leaves their shop meets my print?

Quality inspector using a CMM machine to verify CNC part accuracy

A project can stall in the silence between emails. The best manufacturers understand that clear, proactive communication is just as important as machining skill. You should have a single point of contact—a project manager who knows your job inside and out and provides updates without you having to chase them down. This transparency turns a black-box process into a collaborative effort.

Ask yourself: Will I know my project's status, or will I be left wondering?

Can they actually do what you need? Scrutinize their equipment list. Do they have modern 3-axis and 5-axis milling centers, CNC lathes, and perhaps multi-tasking turn-mill machines? Can they handle your material, whether it's common aluminum or exotic alloys? Furthermore, ask about their capacity. A shop that's constantly overbooked might become a bottleneck for your production.

Ask yourself: Do they have the right tools and available time to handle my project now and as it scales?

Modern CNC machine shop with milling and turning equipment

In manufacturing, on time is as important as on spec. A reliable partner has systems in place to track jobs from raw material to shipping. They are honest about lead times from the start and will alert you the moment a potential delay arises. This reliability is what enables true "quick-turn" capabilities—not just rushing, but having an efficient, predictable process you can count on every time.

Ask yourself: Can I trust them to deliver when they promise?

Packaged precision CNC parts ready for reliable shipping

Choosing a CNC machining manufacturer is one of the most critical decisions in your product's journey. By looking beyond the bottom line and evaluating these five factors, you move from a simple transaction to a valuable partnership. You gain more than parts; you gain peace of mind, knowing your project is in the hands of experts who are as invested in its success as you are.

Ready to experience a different kind of manufacturing service? Let's talk about your project.

Previous:How Long Does CNC Machining Take? 5 Key Factors That Impact Production Time

Next:No More/End