1-Pc OK | No MOQ. CNC Machining for Prototypes and Fast Small Batches. Instant quote

Content Guide:Discover 5 key advantages of Wire EDM over conventional machining: precision (±0.002mm), hardened materials, complex geometries, superior finishes, and cost savings for low-volume parts.

In modern manufacturing, precision and efficiency are critical. While conventional machining methods like milling, turning, and grinding have long been industry standards, Wire Electrical Discharge Machining (Wire EDM) offers unique advantages that make it indispensable for certain applications. This article explores five key areas where Wire EDM outperforms traditional machining—helping manufacturers achieve higher accuracy, better surface finishes, and cost-effective production of complex parts.

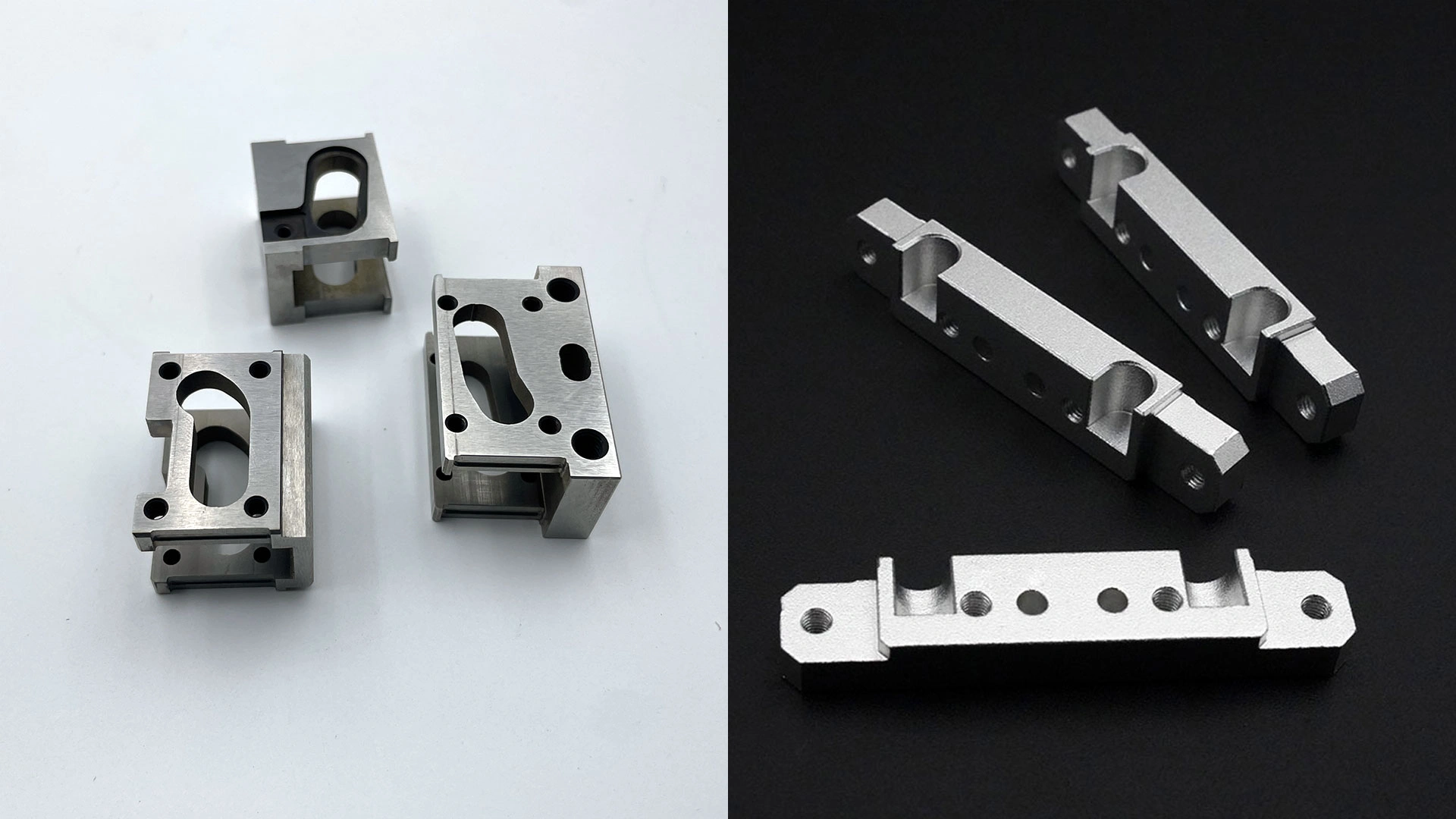

Wire EDM (left) vs. conventional milling (right) – each has distinct advantages depending on the application.

Conventional machining relies on physical cutting tools, which can wear down, introducing errors over time. Wire EDM, however, uses electrical sparks to erode material, eliminating tool wear and maintaining consistent precision. This makes it ideal for:

Micro-machining (thin slots, tiny holes)

High-tolerance aerospace components

Medical implants requiring ultra-fine details

Wire EDM achieves micron-level precision, impossible with traditional methods in many cases.

Traditional cutting tools struggle with hardened steels, titanium, and carbides—often requiring multiple setups and tool changes. Wire EDM cuts any conductive material, regardless of hardness, because it doesn’t rely on mechanical force. Benefits include:

No annealing or softening required

No tool breakage risk

Reduced post-processing

Milling and turning require multiple operations for intricate shapes. Wire EDM can produce complex contours, sharp corners, and fine details in a single pass, thanks to its non-contact cutting method. This is crucial for:

Mold & die manufacturing

Prototyping intricate parts

Electrode machining for EDM

Grinding and polishing are often needed after conventional machining to achieve smooth finishes. Wire EDM can produce near-mirror finishes directly, reducing secondary operations. Key advantages:

Lower Ra values without additional steps

No burrs or mechanical stresses

Ideal for sealing surfaces and optical components

While conventional machining is faster for simple, high-volume parts, Wire EDM becomes more economical when dealing with:

Low batch sizes (no custom tooling needed)

Exotic/hard materials (longer tool life in conventional methods)

Prototyping & one-offs (reduced setup time)

Wire EDM isn’t a replacement for all machining but shines where precision, material hardness, complexity, and surface finish matter most. Manufacturers should consider it for:

✔ Hardened tool steels & carbides

✔ Micro-machining & tight tolerances

✔ Complex geometries with fine details