Wire EDM Machining Services

Our high-precision EDM wire cutting services deliver micron-level accuracy for the most demanding applications. Equipped with state-of-the-art Sodick machines, we specialize in complex geometries, tight tolerances, and superior surface finishes.

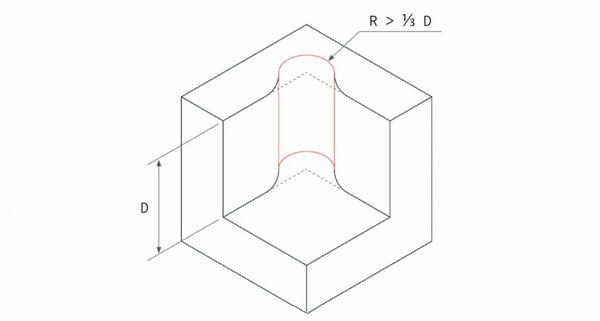

✔ Advanced Technology – Imported Sodick CNC EDM systems ensure repeatable ±0.002mm precision

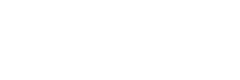

✔ Complex Geometries – Expertly handle multi-axis contours, sharp corners, and thin-walled features

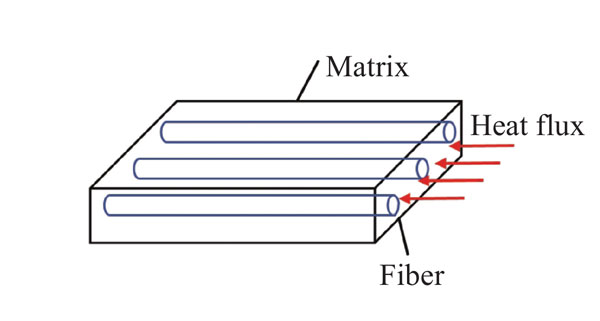

✔ Material Versatility – From hardened tool steels to exotic alloys, we cut it all

✔ Surface Finish Excellence – Achieve mirror-like finishes down to Ra 0.2μm