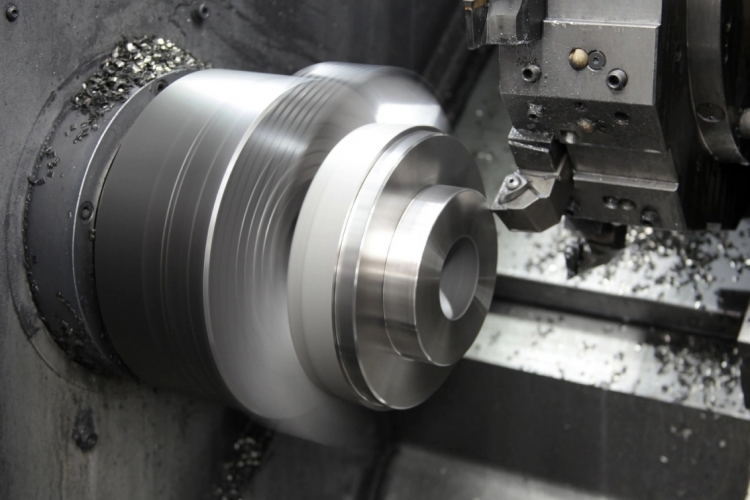

Maximum part size for CNC turning

Part size limitations | Metric units | Imperial units |

|---|---|---|

| Maximum part diameter | 431 mm | 17 in |

| Maximum part length | 990 mm | 39 in |

| Maximum swing over the carriage | 350 mm | 13.7 in |

| Maximum spindle through-hole | 40 mm | 1.5 in |

| Maximum speed: 1700RPM, Motor power: 640W |